Body hacking: A pursuit of enhancement or change to the body's functions through technological means.

I currently have three subdermal implant in my left hand, one diametric magnetized magnet between my second and third metacarpal bone on the back of my hand, one axially magnetized magnet between my first and second metacarpal bone on the palm side, and one NFC + LED implant between my first and second metacarpal bone on the back of my hand. They are all made by Dangerous Things and the exact model is xG3 v1, xG3 v2, and xSIID Blue.

The magnet implant allow me to pick up small object such as coins. It also allows me to feel ferromagnetic material and magnetic field close up, like the alternating magnetic field produced by transfromer in microwaves and laptop charger, and also EM gates at library and stores.

The NFC + LED implant can store up to 858 bytes of data like website url or text accessible by NFC scanner such as a smartphone. The implant also lights up when it is near a NFC field.

Weather satelite such as NOAA-15, 18, and 19, transmit image data real time as they orbit and scan the Earth. The RF signal they transmit is right-hand circularly polarized, and can be received with an antenna like a QFH antenna. I made one out of wire and coxial cable supported by PVC pipe and 3D printed PLA back in my last highschool summer and spend the Covid lockdown receiving satelite image.

The satalite also send temperature data so you can know exactly how hot the ground is at a location or how cold the top of the cloud is if that area is covered by cloud. The image quality is quite good considering that the south and north of my antenna was blocked by houses and tress. Rooftop would be the ideal location but there was no way the antenna can survive the windy Calgary summer up there.

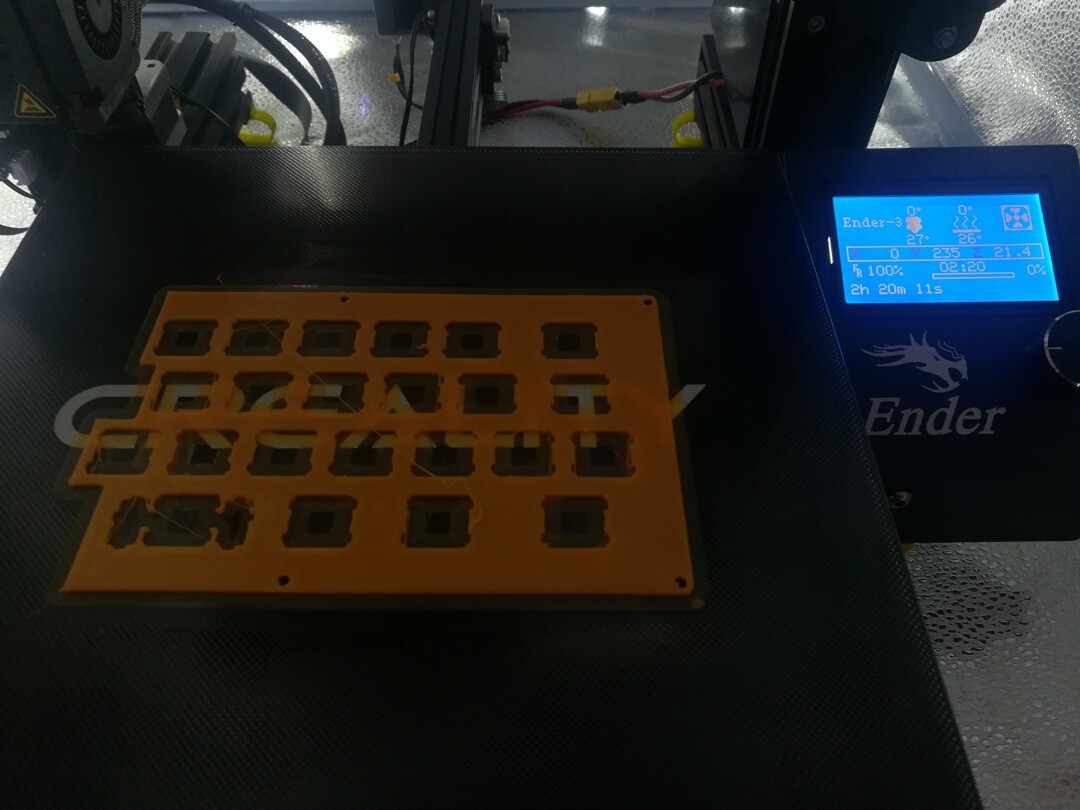

For my IB CAS project, I chose to go with a creative project, which is to make a custom keyboard without a PCB. Based on the spare keycap I had for an minivan keyboard, I 3D printed the plate for the keyboard on my Ender 3.

After that, the keyboard switches are attached. The switches are connected in a matrix of wire that are hooked up to a microcontroller so it can determine which switch is pressed by the row and column wire. The process is long and tedious but at the end you get a nice little keyboard.

Here is what the front of the keyboard looks like.

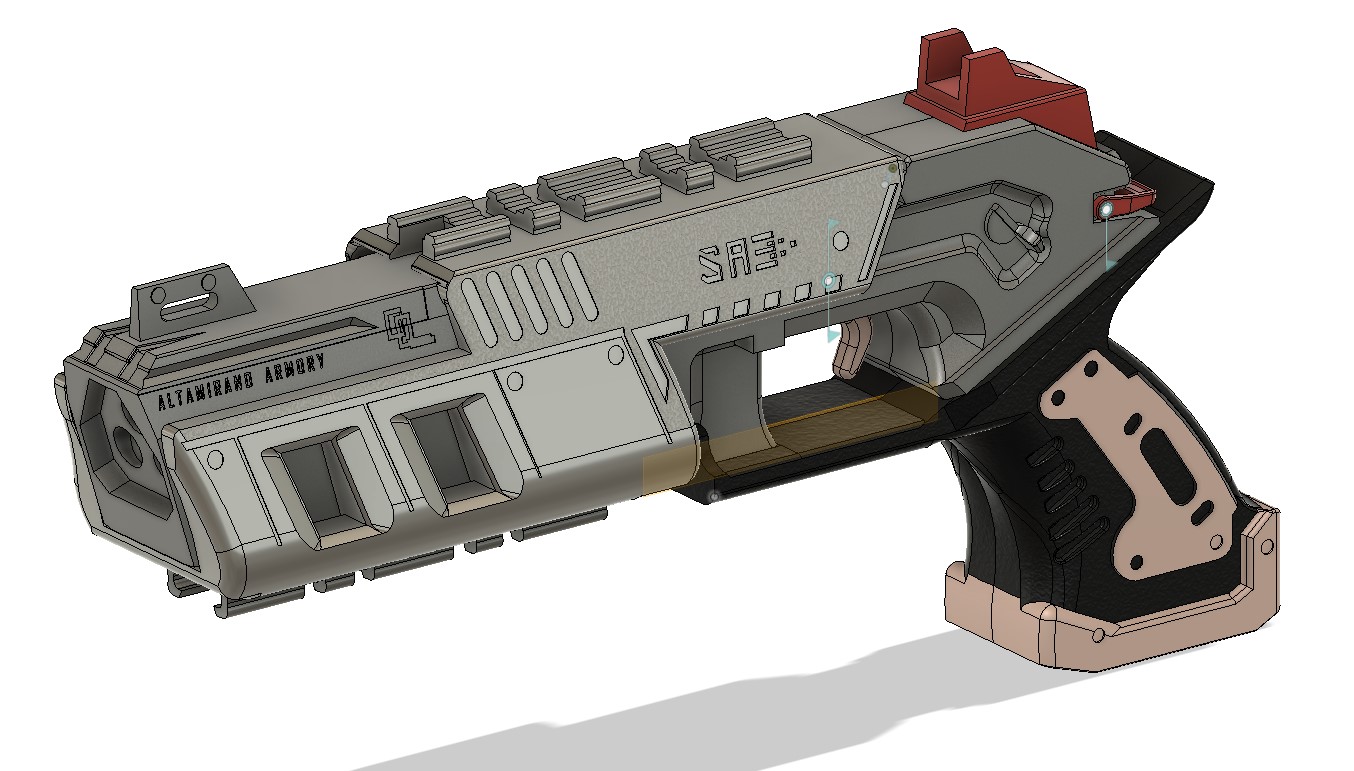

When I first got into 3D printing and CAD back in highschool, I thought that the best way to learn is to model something I liked.

I made this mozambique shotgun pistol prop just a few weeks after I first learned Fusion 360. While it took me 1-2 weeks of learning and modelling, my CAD skill imporved significantly during that time. The pistol contains 14 parts and a spring loaded trigger and slide.

I beign modelling more things and posting them on Thingiverse, where my models has accumulated over 6500 downloads. This eventually led to people contacting me to make custom model and me becoming a freelance 3D modeller on Fiverr.